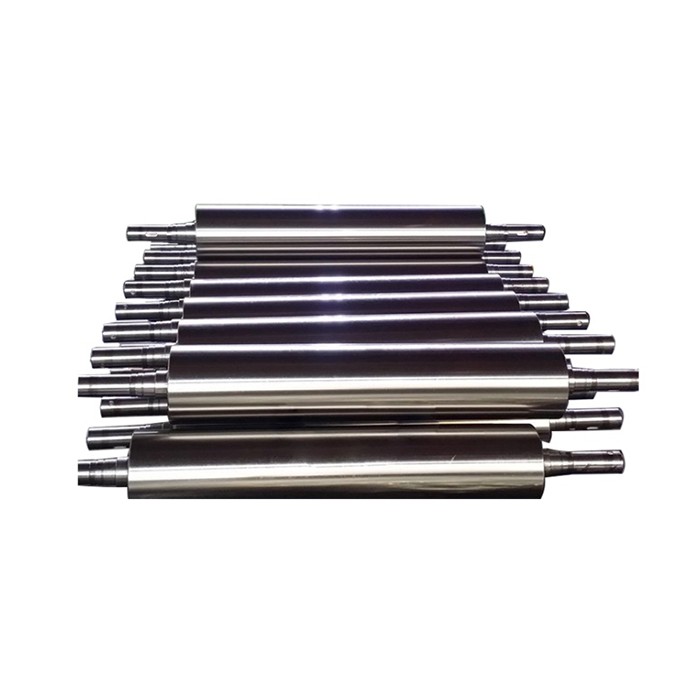

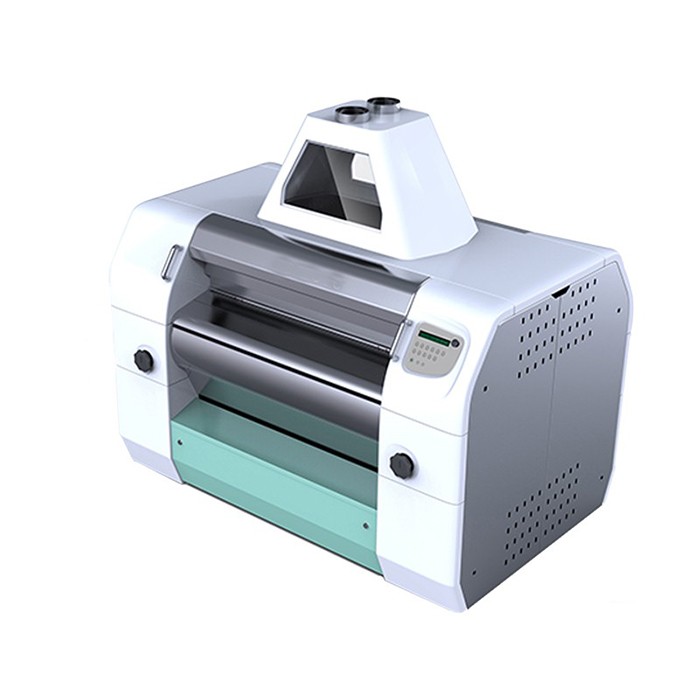

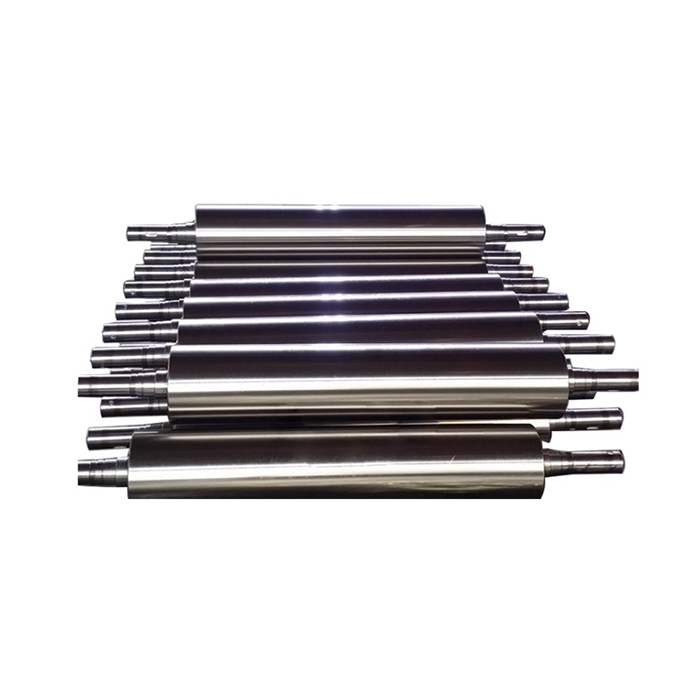

Roller for Roller Mill Machine

- AGS

- JIANGSU

- 30 DAYS

Roller is the key component of mill. They directly affect the flour yield and the quality of the final product.

Roller for Roller Mill Machine

High quality roller needs the unity of the abrasion resistance and toughness. And its hardness is a constant, structural characteristic is in accordance. In the production process, high quality roller can improve the use efficiency and lower the power consumption; In the process of repair, it is easily to machining and prolongs service life.

First, our multi-metal, centrifugally casted roller guarantee an alloy chilled cast iron for a perfect surface of even hardness for the outer layer as well as a high quality cast iron for the softer inner layer.

Second, roller is individually checked by the Spectro-Analysis method.

Third, the most advanced processing equipment to ensure that roller can meet the demands of all kinds of craft.

Fourth, we will through ultrasonic flaw detection, curve inspection and dynamic balance inspection to ensure the highest quality standard.

Firth, strict quality control can ensure the quality of each roller of traceability.

Sixth, chambered roller for reduced temperature is an optional feature for improved flour quality.

Seventh, special customer designed roller is part of our manufacturing program.